Having pummelled the vertigo-inducing Daytona banking for 24 hours, 724 laps and 4,439km, the Gulf-Wyer Porsche 917K driven to victory in the 1970 World Sportscar Championship season-opener by Pedro Rodríguez, Leo Kinnunen and Brian Redman wore its battle scars with pride.

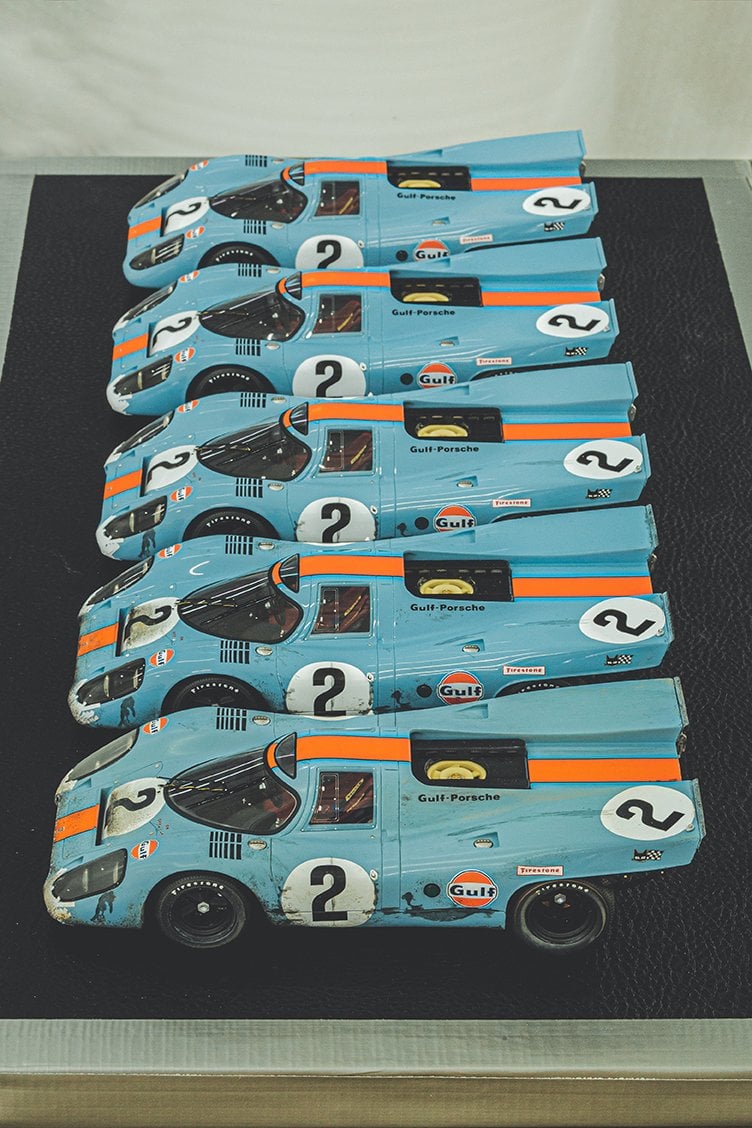

The delicate nose had been effectively sandblasted by debris revealing the raw glass-fibre beneath, the headlight clusters were secured by hastily applied strips of duct tape, the left-hand headlight lens had actually cracked, and the once-shiny duck egg blue bodywork was smeared all over with road grime and rubber.

After the 1970 season had concluded, the Daytona-winning 917, chassis 015, was converted to Spider configuration by the factory and all traces of its dominant debut were sadly erased in the unrelenting quest for success. Now Amalgam Collection, the British purveyor of the world’s finest model cars, has immortalised the significant Works-backed Porsche in the exact condition it crossed the finish line at Daytona 50 years ago, warts and all.

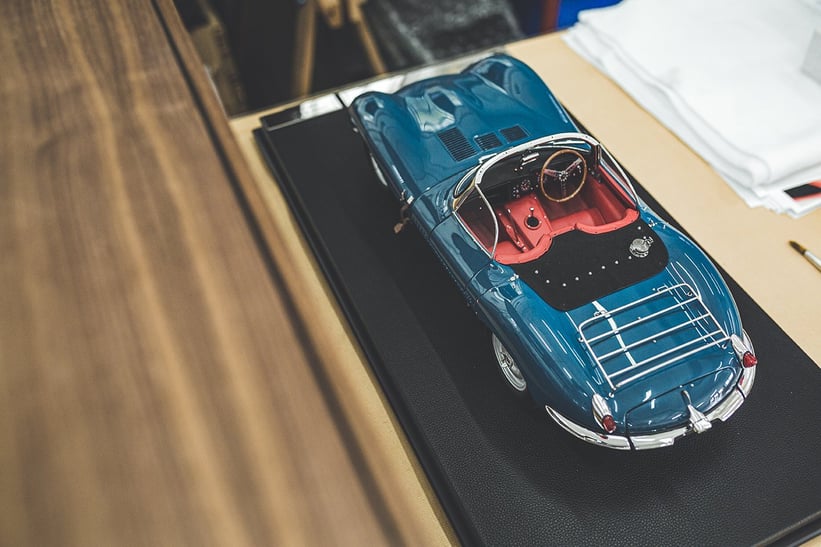

Amalgam’s story began in the 1980s, when it specialised in architectural modelling and product prototyping for prestigious and pioneering industry leaders including Foster & Partners and Dyson. Following deals struck with the Williams and Jordan Formula 1 teams in 1995, Amalgam’s focus switched to cars. Ever since then, it’s forged a reputation for building models that astonish with their accuracy and realism, and fostered close relationships with the automotive world’s biggest brands.

“Our mission is to use our artistry and ingenuity to build models that, when viewed in photographs, look indistinguishable from the real thing,” explains company founder Sandy Copeman during our recent visit to Amalgam’s Bristol studio, a dream factory that doesn’t so much as capture your imagination than hold it hostage – if you want to fall in love with cars all over again, we’d thoroughly recommend a visit. “If a photograph of one of our models fools you into thinking it’s the real car, then our job is done.”

The model making process at Amalgam is one that fuses artistry, artisanal craftsmanship and precision with creativity, imagination and passion. Think along the lines of haute horology, encapsulated by masterminds such as Richard Mille (who Amalgam happens to work closely with). At first glance it might be easy to scoff at the prices of Amalgam’s models, but once you understand and appreciate the time and lengths gone to in the creation of each, the value placed upon them makes a lot more sense.

For a little context, a 1:8-scale Amalgam model boasts at least 1,200 individual parts if it’s a modern road car and up to 3,000 parts if it’s a classic. A single wire wheel for example, has 72 spokes, 72 nipples and a further 10–15 hub parts. That’s edging towards 1,000 pieces for the wheels alone. And the development process prior to casting of the resin parts and assembly is between 2,500 hours if it’s a modern Formula 1 car and 4,500 hours for a complex classic car.

In short, that time includes making a set of patterns (on average 50 percent of which are 3D-printed) from which moulds can be taken, taking up to 1,000 photographs, digitally rendering the model using manufacturer-provided CAD data or digital scans, machining or photo-etching metal pieces, and making silicone moulds for each individual resin part.

“You can’t just put your CAD or drawings through a magic scanner and pop out a ready-baked 1:8-scale version of a car,” Copeland quips. “You have to think carefully about how you’re going to construct it while representing the car as accurately as possible.”

The decision to start ‘race-weathering’ its models was taken party because it provided Amalgam with an opportunity to flex its creative muscle, but also because the company is in part owned by Motorsport Network, an umbrella media group that counts the extensive Motorsport Images archive as one of its brands. Such an archive provides plentiful, high-quality photography of motorsport history’s most famous races, serving as a perfect reference point from which to recreate a specific car at the end of a specific race.

“Replicating not only the dirt but also the damage is exactly the kind of challenge we relish because there’s even more scope to exercise our artistry and cleverness,” Copeland continues. “And because we’re working to a set of photographs, there’s always a solid reference to refer back to.”

The first model to receive the race-weathering treatment was the Ferrari 250 Testa Rossa affectionately known as ‘Lucybelle II’, which finished seventh overall at Le Mans in 1958. The Testa Rossa was followed up by the Ueno Clinic-sponsored McLaren F1 GTR that, against all the odds and in atrocious conditions, won the French endurance classic in 1995. The 1970 Daytona 24-winning Porsche 917K is the latest model to be completed.

There are two fundamental techniques to the weathering process. Firstly, a small spray gun is used to apply details. “You can achieve a lot with spraying in terms of replicating textures, which is a technique that actually comes from architectural models,” Copeland explains. “If you look at the front of the 917, we didn’t actually sandblast the paint but rather sprayed tiny dots in the colour of the raw glass-fibre where the paint had been chipped away.”

Secondly, various different water-based paints washes are used to cover larger areas. “Such a real surface has an immense complexity of colour and the most important part when it comes to making the dirt look authentic is to use many different layers – of course, it’s a case of trial and error, which is why water-based paints are vital, but we’re drawing on a box of established techniques.”

Just one of Amalgam’s master craftsmen is responsible for the weathering process, taking three to four days alone to complete the first model, which is then used as a reference for the following pieces. Our favourite detail on the Porsche is the shattered headlight lens, which was actually laser cut using a tiny jig made especially for that one piece.

All three of the aforementioned models were produced in the larger 1:8 scale, although now Amalgam is applying the weathered look to its smaller-sized offering for the first time and building a limited edition of 100 Porsche 917Ks in 1:18 scale. And it’s these we’ve come to ogle at Amalgam’s studio in their varying stages of completion. “We had such a good reception to the larger 917K that we decided to do a 1:18 scale piece as a result. It’s not necessarily a harder process, but rather an equally difficult one.”

We’ve always found racing cars kept in their original, as-raced condition to be a beguiling spectacle, because they tell a thousand different stories from one moment in history and allow our imaginations to run wild. The best part about Amalgam’s Porsche 917K is that it captures a specific moment in time and an achievement that reflects the hard work and personal stories of hundreds of people, both before and during the race.

The real chassis 917-015 has since been painstakingly restored back to its closed-coupé Daytona configuration (complete with window atop the windscreen to aid visibility on the banking) and is frequently exercised at historic events across the world. And that’s a fantastic thing. Gone, however, are the grime and the battle scars amassed during those 24 flat-out hours in January of 1970. Thanks to Amalgam’s three-dimensional small-scale facsimile, we can revel in that victorious moment to our heart’s desire. Truly, the best of both worlds.

Photos: Robert Cooper for Classic Driver © 2020