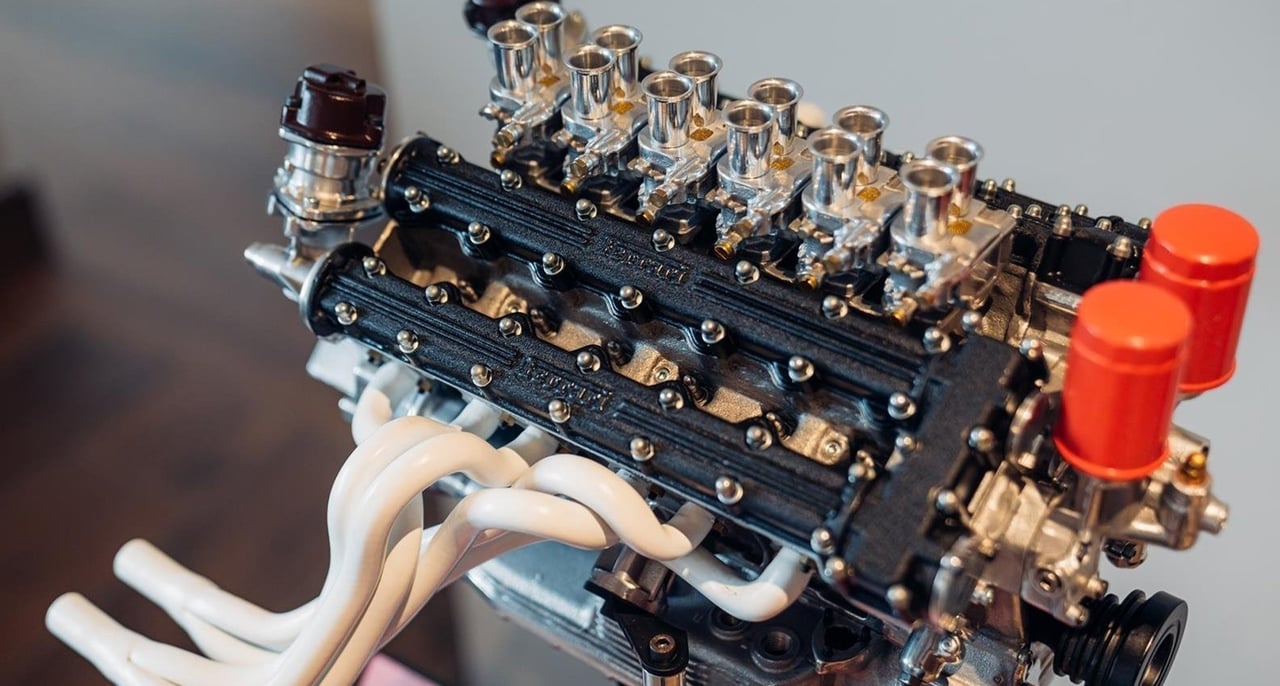

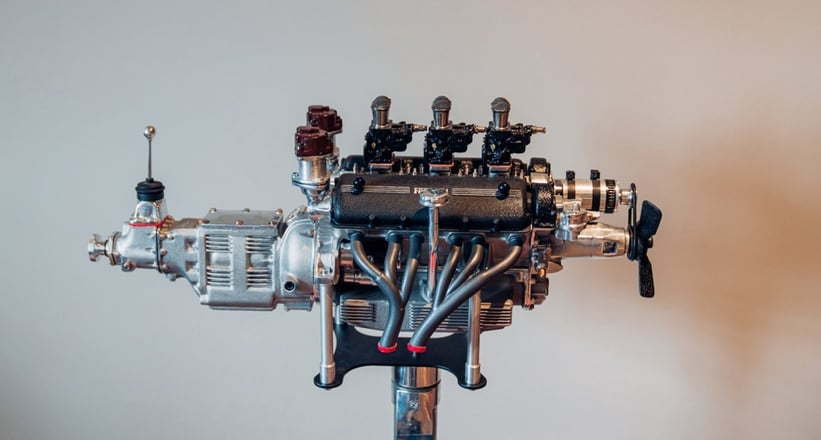

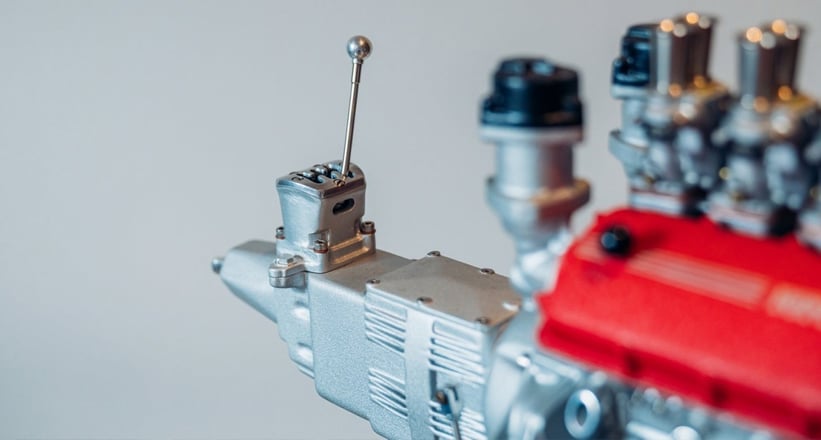

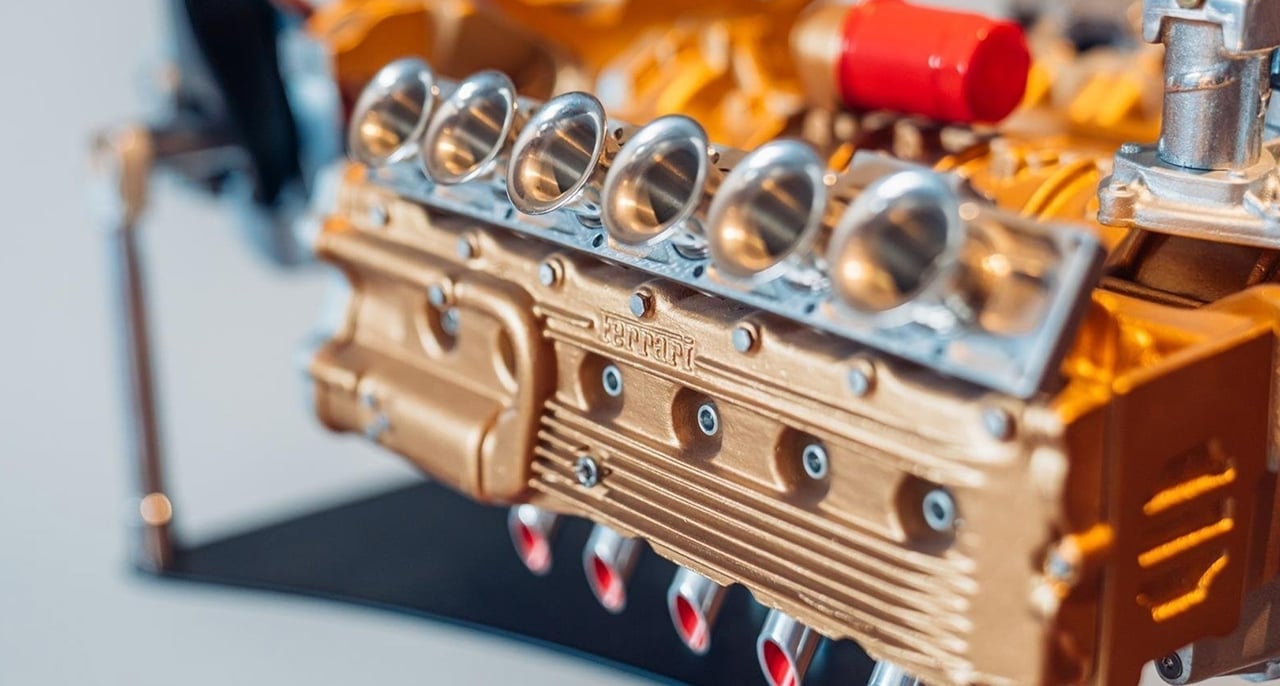

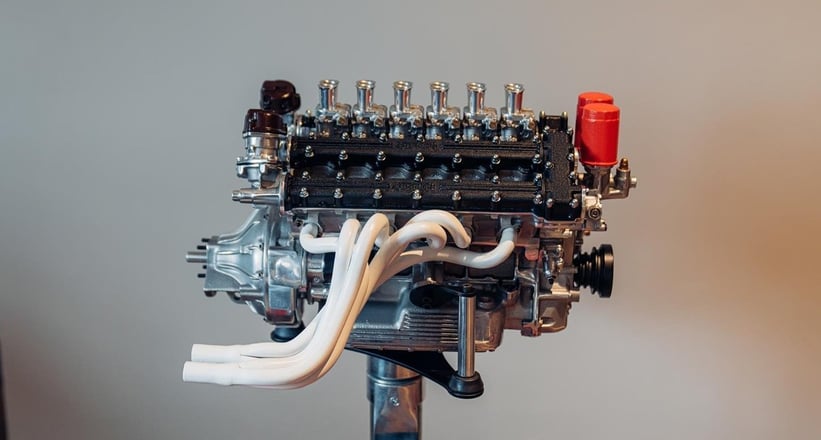

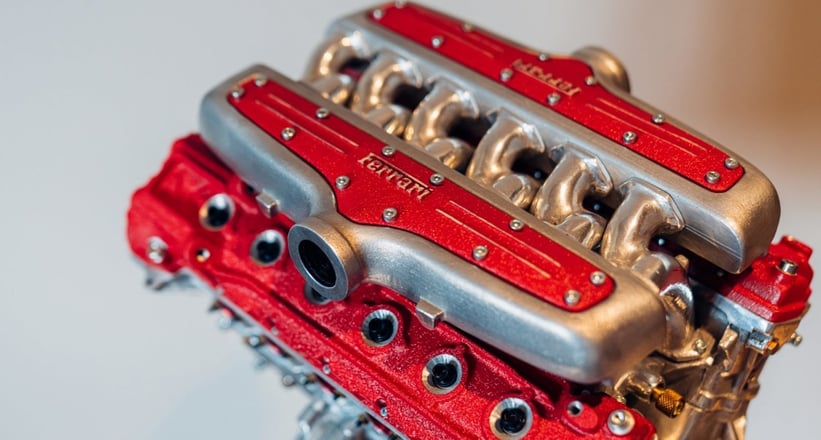

There are many models that impress with their precision craftsmanship and attention to detail in the Classic Driver Shop, but these 1/3 scale replica Ferrari engines available through DK Engineering take things to a whole new level. Utilising many of the techniques Ferrari used in period, master artisan Terzo Dalia’s creations are built in ultra-limited numbers, with each engine taking over a year to produce and assemble, and weighing in at a hefty 16 kilos.

Officially recognised by Luca de Montezemolo, who awarded Terzo Dalia first prize for his creations at Ferrari’s Golden Jubilee, these aren’t any ordinary static models. In fact, no adhesive is used whatsoever in the engines’ construction. The Ferrari 250 TR’s Colombo V12, for example, uses over 240 parts, and is held together with no fewer than 470 screws. Even more impressively, these fully-synchronised engines rotate in the exact firing order, with the 12 separate pistons linked as they would be in full scale.

Using his factory connections, Terzo Dalia starts the process of recreating these 1/3 scale engines by fully disassembling a real engine to take exact measurements. Parts are then first-hand carved from wood and test fitted, before reaching the sand-casting and formation stages. Included among the engines that have undergone the miniaturisation process are the 599’s Enzo-derived V12, a 1975 Ferrari 312 Boxer F1 Engine, and the iconic V12 found in the Ferrari Daytona. These engines are true works of art, and are even displayed in the Ferrari Museum in Maranello, so if you’re a serious Ferrari collector then this could be the centrepiece your garage needed.